News Details

The difference between polyurethane casters and nylon casters for manual hydraulic handling vehicle accessories

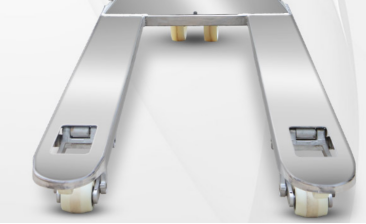

Manual hydraulic handling vehicles are small handling equipment commonly used in factory workshops, logistics warehouses, and other cargo transportation scenarios. Casters are very important components in handling vehicles. Currently, casters can be made from four materials: nylon, polyurethane, rubber, and synthetic rubber, but only polyurethane casters and nylon casters are commonly used.

The manufacturing materials of polyurethane casters and nylon casters are different. Polyurethane casters are composed of acrylic esters (single) and hydroxyl compounds. Their advantages lie in friction resistance and low noise, making them suitable for use in environmentally friendly and dust-free industrial workshops.

Nylon casters have low transfer assistance, lightweight pulling, corrosion resistance, strong load-bearing capacity, and are characterized by heat resistance, cold resistance, and wear resistance. They are also relatively lightweight and widely used in the transportation industry.

It is worth noting that although the casters of manual hydraulic transport vehicles have these good properties, it does not mean that they will not be corroded or worn. Factors such as prolonged use and harsh environments can cause the casters of transport vehicles to lose their basic walking function.